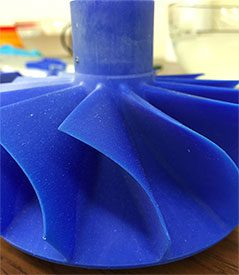

Apollo Products Inc. and Trucast Inc. are pleased to announce the purchase of our new 3D Systems Wax 3D Printer and a Stratasys 3D Plastics Printer. We are now able to print Rapid Prototype Wax and Plastic parts as we continue to service the Casting and Aerospace Industry. Our printers have a variety of different quality settings to accommodate virtually every need in prototyping.

Our Wax Printer uses a wax with 0% ash content making our printed parts clean at the point of cast. Our plastics machine can do hard plastics in a variety of colors and clarity. It can also print a variety of soft rubbers ranging from 60 to 80 on the shore scale. Bio-Compatible materials for medical use can be printed as well. Our goal is to 3D print your ideas with the ultimate in precision and versatility.

Common usage examples:

- Wax Casting Prototypes

- Wall Templates

- Rubber Airflow/Waterflow Boots

- Short run (up to 100 shots) molds are capable with ABS plastics

- Functional Plastic Prototypes

- Prototype Jigs and Fixturing

Our build plates sizes and layer thicknesses are as follows:

- Wax Machine – (11.75” x 7.3” x 8”) – .0016 layer thickness

- Plastic Machine – (11.57” x 7.55” x 5.85”) – .0006 layer thickness