Gauge and Fixture Division

About Us

Gauge and Fixture Division

Our Gauge and Fixture Division was founded in 1994 by Jesse Baden and Michael Scanlon (as Apollo Products) pooling together their many years of diverse experience in the aerospace tooling industry. Over time, they have developed a successful business focused on quality products for our customer base.

Our team specializes in the design and manufacturing of gauges, fixtures, and component wax dies.

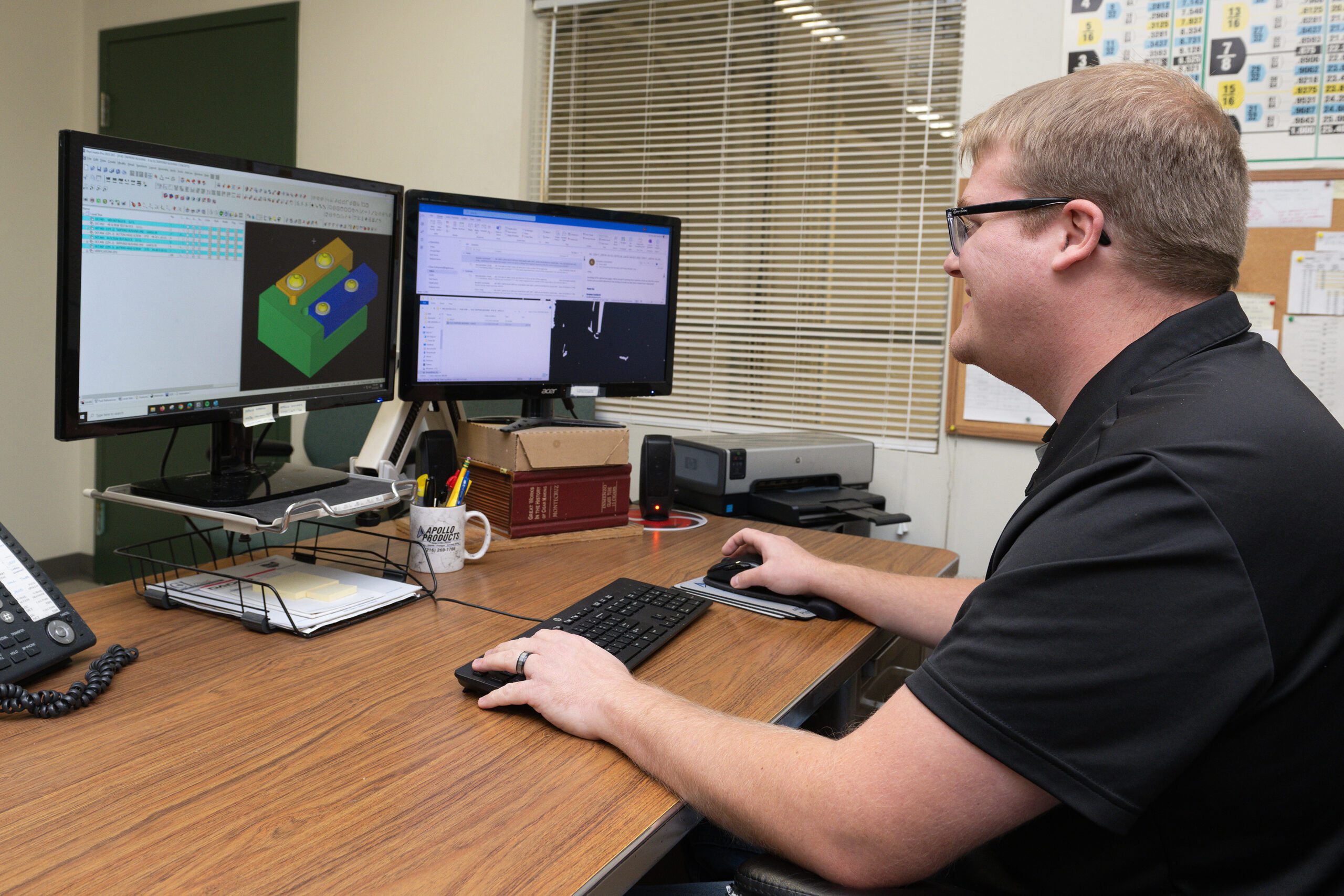

We feature an engineering team with over 40 years of combined experience to design to customer need and specifications. Along with our dependable engineering team, we also boast a tool shop with experienced machinists and assemblers. Our tool shop also contains multiple 5 axis machining centers and 3D printers that allows our employees to demonstrate their expertise.

We stress continued emphasis on delivering first-rate products, both on time and to customer specifications. The commitment to ongoing quality and service has allowed our Gauge and Fixture Division to become ISO 9001:2015 Certified. We are also in the GE yellow pages as a supplier of non-traditional machining services.

Hidden Item

- 6 Hand Surface grinders (4 6X18, 2 6X12)

- 1 Automatic wet surface grinder (12 X 24)

- 8 Bridgeport Milling Machines

- 3 30 X 16 Fadal CNC Milling Machines

- 2 EMC Fadal CNC Milling Machines

- 2 60 X 30 Fadal Milling Machines

- 1 Mori Seik DV 5100

- 1 DMG ECO 50 (5 Axis)

- 1 Mikron HPM 450U (5 Axis)

- 1 Moore Jig Grinder

- 1 Agie-Charmilles Wire EDM

- 1 Perseo-Erie Fast Hole EDM

- 1 LK (LK V 8.7.6) CMM

- 1 LK (G-90C) CMM

We work to customer specifications and tooling manuals.

Some commonly used materials include:

- O1 Tool Steel

- D2 Tool Steel

- A2 Tool Steel

- M2 Tool Steel

- S7 Tool Steel

- H13 Tool Steel

- P20 Tool Steel

- 4140 Tool Steel

- 11L17 Leaded Alloy

- 12L17 Leaded Alloy

- 1018 Cold Rolled Steel

- 1020 Hot Rolled Steel

- 6061 Aluminum Alloy

- 7075 Aluminum Alloy

- Cast Nylons & Delrin

- Machinable Waxes

Our tool and die shop currently employs 16 people and has all of the standard milling and grinding capabilities. We also have a bank of CNC milling machines giving us the ability to manufacture tooling for the vast majority of all of our customers’ parts. We use ProCam/CamWorks CNC programming software and our design department utilizes Kubotek’s KeyCreator full 3D CAD software. This software allows us to import almost any file format you have so we can design using your part models.

Gauges

- Chord Width Gauges

- Pitch Thickness Gauges

- Trailing Edge Thickness Gauges

- Snag Grind Gauges

- Guillotine Contour Gauges

- Non contact Laser Gauges

- Fully Automated electronic Gauges

Fixtures

- CMM Fixtures

- Marking Fixtures

- Multiple station CNC/Tombstone Fixtures

- Impact Grind (Snag) Fixtures

- Milling and Drilling Fixtures

- Test Fixtures for Water flow and Airflow

Component Wax Dies

- Runner dies

- Sprue dies

- Heat Shield Dies

- Gating Dies

- Chill Dies